FKDC Blogs

- National Level workshop of FKDC at Manipal Institute...April 11, 2024

- FMAE FKDC X MIT MANIPALApril 11, 2024

- FMAE FKDC 2024: The Premier Destination for Go Kart...March 14, 2024

- MITS MOTORSPORTS celebrating their win in FKDC Season...November 16, 2023

- FKDC Final Event dates are out | It will be organized...October 5, 2023

- National Level workshop of FKDC at Manipal Institute...

-

Recent Courses

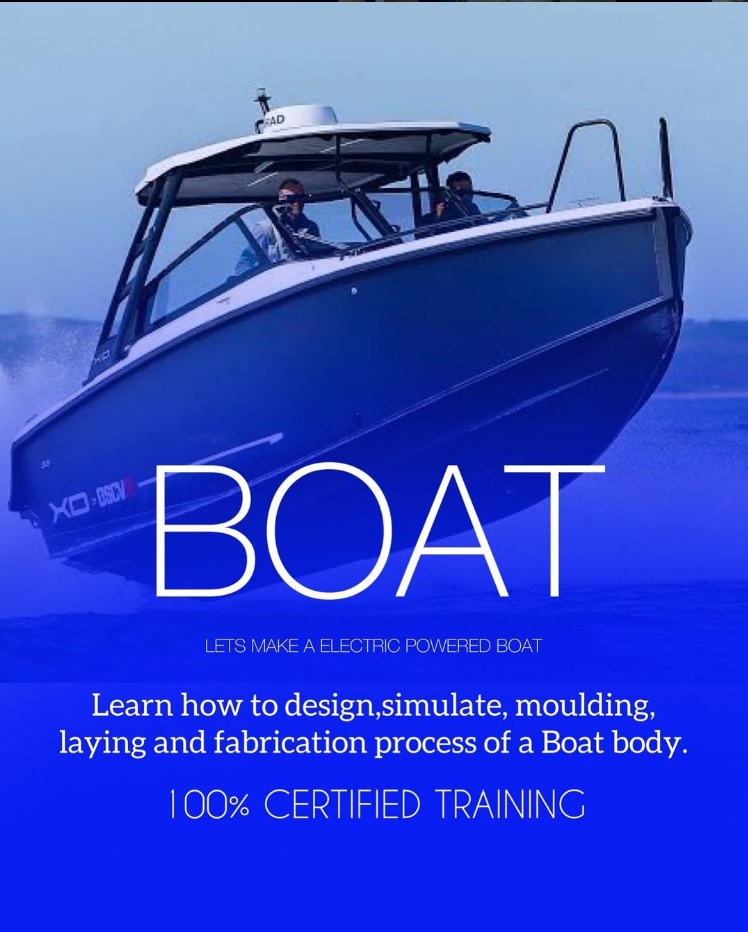

MANUFACTURING OF BOAT BODY

The internship covers the complete end-to-end designing and Manufacturing of...28,500 ₹12,000 ₹MANUFACTURING OF MOTO GP

The internship covers the complete end-to-end designing and Manufacturing of...28,500 ₹12,000 ₹ Blogs on FFS

- Where is FFS India Held?May 30, 2023

- Who is the Organizers of FFS India?May 30, 2023

- What is FFS India?May 30, 2023

- Where is FFS India Held?

Training Blog

- Kickstart Your Career in the Electric Vehicle Sector...March 14, 2024

- Learn to Manufacture Electric MotorcycleMarch 14, 2024

- CET posts resounding performance at kart design competition...August 16, 2023

- Please peruse the article in The Times of India detailing...August 16, 2023

- On Job Training 2023July 28, 2023

- Kickstart Your Career in the Electric Vehicle Sector...